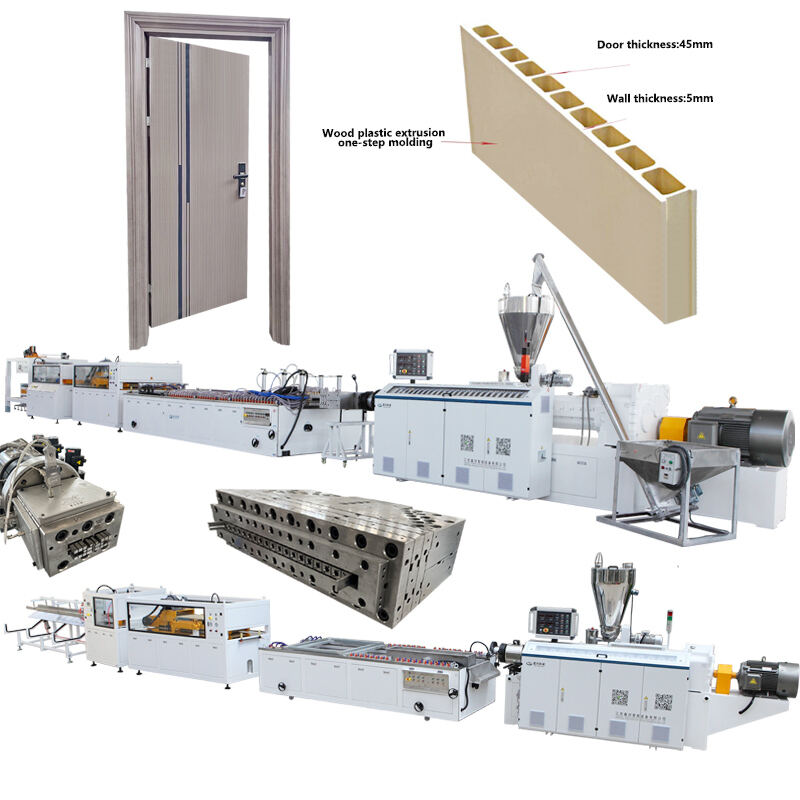

Explicação Detalhada do Princípio de Funcionamento do Extrusor de Painel para Porta WPC: O Processo Completo desde Matérias-Primas até Produtos Acabados

2026

O princípio de funcionamento de uma extrusora de painéis para portas WPC é na realidade um processo automatizado em circuito fechado, desde a matéria-prima até os produtos acabados. A Xinhe Machinery ajuda você a entender isso claramente:

I. Processo Principal em Três Etapas

1. Mistura da Matéria-Prima: grânulos de PVC, farinha de madeira, pó de cálcio e aditivos são misturados em alta velocidade e uniformemente no sistema de mistura.

2. Moldagem por extrusão: Os materiais misturados entram no extrusor duplo-parafuso cônico WPC, onde os parafusos rotativos impulsionam o material para frente. Após o aquecimento e fusão, o material é moldado.

3. Pós-processamento: A chapa extrudada em alta temperatura entra em um molde de conformação a vácuo para controle de suas dimensões. Em seguida, é lentamente resfriada por um suporte de refrigeração para evitar deformação. Finalmente, é transportada suavemente por um sistema de tração servo e cortada automaticamente no comprimento desejado por uma serra voadora.

II. Equipamentos e Detalhes do Processo

1. Extrusora: O modelo principal utiliza um diâmetro de parafuso duplo de 92/188 mm, com potência total de 110 kW, e pode produzir estavelmente entre 600 e 800 kg por hora.

2. Moldagem a Vácuo: Controle preciso das dimensões da seção transversal garante espessura uniforme do painel da porta. Um molde frio de 3 m de comprimento garante resfriamento e moldagem, enquanto uma mesa de termoformagem a vácuo de 6 m de comprimento assegura produção estável. Um comprimento excessivo duplicaria a dificuldade de inicialização da máquina, pois o vácuo só é ativado quando o painel da porta alcança a máquina de tração.

3. Resfriamento e Prevenção de Deformação: Suportes de resfriamento em múltiplos segmentos reduzem lentamente a temperatura, prevenindo efetivamente a deformação do produto. A temperatura da água de resfriamento é controlada em 20°C.

4. Tração e Corte: Um sistema servo de tração proporciona transporte suave, e a serra voadora corta automaticamente em comprimento fixo, com erro de corte não superior a 1 mm.

Máquina de Transferência de Painéis: Máquina servo automática de transferência de painéis.

III. Automação e Proteção Ambiental

1. Automação Completa: Toda a linha de produção de painéis de porta WPC requer apenas 2-3 pessoas para monitoramento, permitindo operação contínua 24/7. A capacidade de produção é duplicada em comparação com os métodos tradicionais, enquanto os custos com mão de obra são reduzidos pela metade.

2. Design Ambientalmente Amigável: O design do equipamento incorpora conceitos de proteção ambiental, alcançando uma situação vantajosa tanto para o meio ambiente quanto para a eficiência.

EN

EN

AR

AR

BG

BG

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MK

MK

HY

HY

AZ

AZ

UR

UR

BN

BN

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ